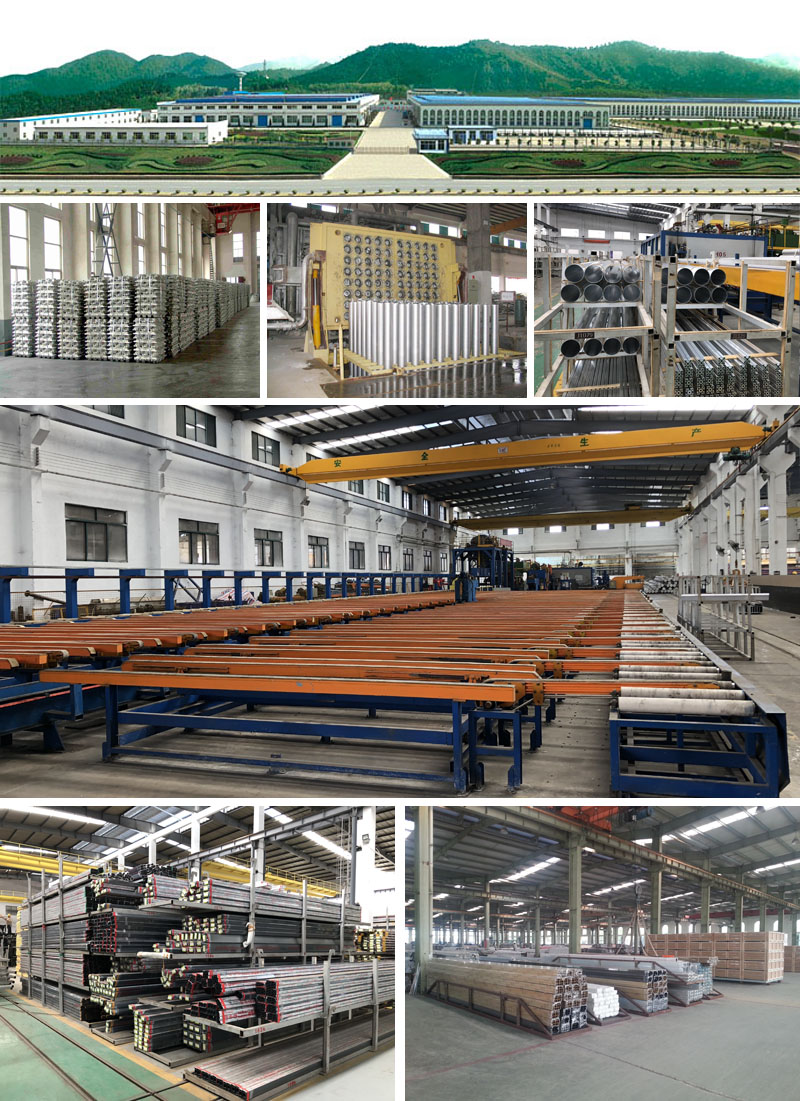

Plant View

As a leading manufacturer of extruded aluminum, we have been specializing in developing and producing high quality aluminum extrusions since 2003. In addition, with our in-house fabrication shops for a variety of further machining works, we provides cost effective aluminum components and fabricated products for commercial, residential and industrial projects.

Specifications on aluminum extrusion profiles

Material: 6000 series aluminum alloy, 6063, 6061, 6005, 6082

Temper: T5, T6

Surface Treatment: mill finish, anodized in natural silver/black/golden/champagne, powder coated, electrophoresis

Press machines: ranging from 600 tons to 5000 tons

Extrusion shapes: up to 650mm in circle size

Wall thickness: 0.8 mm to 30 mm

Weight: 0.15 kg/m to 30 kg/m

Drawing: technical drawings required, our engineering team can also assist in drafting based on the samples or concepts

Standard: GB/T 6892-2006, ANSI H35.2, EN755-2, EN12020-2, JIS H4100

Production capacities: 8,000 tons per month

Packaging: poly bags, cartons, pallets or as required

Typical applications: tubes and pipes, aluminum angles & corners, conduits, aluminum heat sinks, aluminum led strips, solar panel mounting frames, motor housing, aluminum module frames, assembly lines, board framing, aluminum windows & doors, curtain walls, aluminum handrails, aluminum furnitures.

Additional Machining & Fabrication

In our fabrication shops we provide custom aluminum fabrication based on extruded aluminum, including saw cutting, cnc machining, forming, bending, welding, assembly and finishing.

Many aluminum extruders focus on the output of extrusions and don’t invest enough to ensure its plant and equipment can provide their clients with custom aluminum manufacturing services. But with our in-house fabrication abilities, we can build from start to finish to provide our clients with high quality custom aluminum products at competitive rates.

We truly are one-stop solution for customizing aluminum components, you can rely on us to provide all of you needs.